Artificial diamonds and the snowflake chamber, pt. 2

Artificial diamonds, we read in Wired, can be "created in a chamber that mimics geologic conditions" – they are manufactured, in other words, inside surrogate earths.

This chamber of geological mimicry is really "an 8,000-pound machine that use[s] hydraulics and electricity to focus increasing amounts of pressure and heat on the core of a sphere." Such hydraulic pressure recreates "conditions 100 miles below Earth's surface, where diamonds form. Put a sliver of diamond in the core, inject some carbon, and voilà, a larger diamond will grow around the sliver."

All of this is done in a "30,000-square-foot factory, located in an industrial park outside Sarasota, Florida." Here, "a roomful of Russian-designed machines spit[s] out 3-carat roughs 24 hours a day, seven days a week."

The warehouse is run by a company called Gemesis. Its owner jokes that, add another warehouse or two, and soon he'll have himself "a proper diamond mine."

[Image: two yellow diamonds by Gemesis. The diamonds are apparently undetectable as manmade except by the most expensive machinery De Beers can throw at them.]

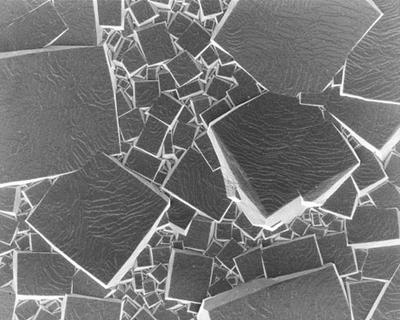

[Image: the inner crystallography of a diamond – looking almost as if "Black Square" by Kazimir Malevich hit the bottle and went to Kinko's with some time to kill:]

But Gemesis does not have the only – in fact, does not have the best – method for producing artificial diamonds. Apollo Diamond, based in Boston – in "a suburban strip mall occupied by a fitness gym and a graphic design company" – uses a process called chemical vapor deposition, or CVD. CVD "has been used for more than a decade to cover relatively large surfaces with microscopic diamond crystals. The technique transforms carbon into a plasma, which then precipitates onto a substrate as diamond."

The diamond precipitates, forming "when a plasma cloud rains carbon onto diamond wafers" – but perhaps rain is not the appropriate analogy here.

Using CVD, "diamonds could conceivably be grown in large bricks" – kicking off a whole new realm of architectural possibilities that the Wired article does not otherwise describe: a new diamond-walled Notre-Dame of constant refraction and transparent vaults, precision-cut into spires that would put Gaudí to shame.

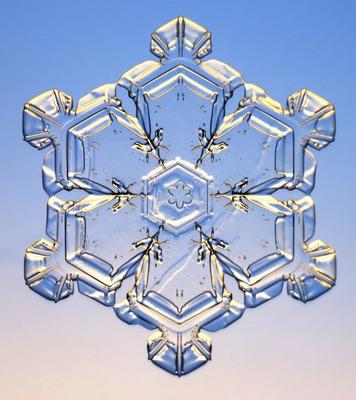

But it's the precipitation that interests me here, especially in the context of snow: "To grow single-crystal diamond using chemical vapor deposition, you must first divine the exact combination of temperature, gas composition, and pressure – a 'sweet spot' that results in the formation of a single crystal. Otherwise, innumerable small diamond crystals will rain down" – or snow down, as the case may be.

An artificial earth-chamber that snows diamonds.

Perhaps, then, BLDGBLOG needs to update its proposal for a snowflake incubation city, and reimagine it as a city that constantly snows diamonds, thousands upon thousands of diamonds, snowing down from the roofs of cathedrals, filling inland canals, blowing through elevator shafts, falling quietly behind glass walls with a light rhythmic tap and rush.

Comments are moderated.

If it's not spam, it will appear here shortly!

Very cool! Reminds me of the snowflake images of Wilson 'Snowflake' Bentley( http://snowflakebentley.com/snowflakes.htm )

Post a Comment