Fabulous Fabbers

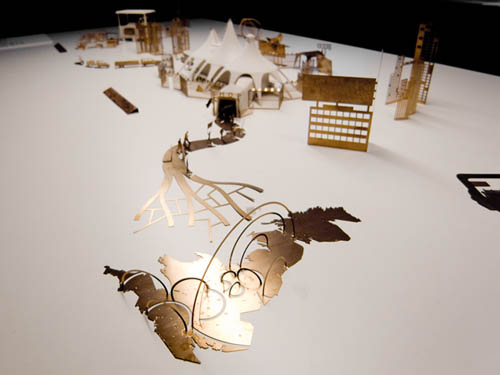

[Image: The circus tent of infinitely flexible, temporary production, from "Fabulous Fabbers" by David Benqué, produced in collaboration with 3D Mintegration].

[Image: The circus tent of infinitely flexible, temporary production, from "Fabulous Fabbers" by David Benqué, produced in collaboration with 3D Mintegration].Designer David Benqué's "Fabulous Fabbers" project asks what the world might look like if "new techniques to manufacture complex, miniaturised and integrated products, with cheaper and smaller infrastructure than the current silicon industry," were to become much more widespread, infiltrating our cities, taking over streetscapes, and becoming ineradicable parts of our everyday lives.

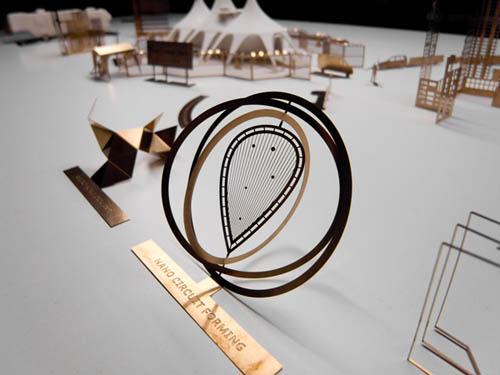

[Image: "Fabulous Fabbers" by David Benqué on display at the Royal College of Art's EPSRC IMPACT! Exhibition, April 2010].

[Image: "Fabulous Fabbers" by David Benqué on display at the Royal College of Art's EPSRC IMPACT! Exhibition, April 2010]."The factories are coming to town!" Benqué writes, describing a reverse-migration of productive landscapes back into our homes and cities. Only these aren't Pittsburghian Satanic mills of large-scale machinery and acre-size factory floors; they are temporary, tiny, and very highly mobile.

That is, Benqué continues, factories "are moving away from the unseen fringes, and into our cities":

- Advances in micro-scale engineering point to a global scale revolution where local, disposable factories produce hi tech goods at our very doorstep. What shapes might this new way of “making things” take within our urban landscape ? From garage-workshops to circus-like temporary structures, from street vendor stalls to vagabond encampments, this project explores the factories of the future and what our relationship to them might be, with the exciting prospect of taking back ownership over our production tools.

[Image: Rogue Factory from "Fabulous Fabbers" by David Benqué].

[Image: Rogue Factory from "Fabulous Fabbers" by David Benqué].For instance, there is the Rogue Factory unit producing "custom high-tech goods"—but "what would the black market of 'special orders' look like?" Benque asks. This "black market of 'special orders'" for things like 3D-printed human organs would also be something quite extraordinary to see, given another two decades' time and cheap-enough bio-ink.

[Images: More view of "Fabulous Fabbers" by David Benqué].

[Images: More view of "Fabulous Fabbers" by David Benqué].Benqué's big-top Mobile Manufacturing Unit, meanwhile, "tours the country, setting up in cities for a few months at a time. As the population welcomes a new source of goods, jobs and manufacturing techniques, it is celebrated as an event."

[Image: Mobile Manufacturing Unit by David Benqué].

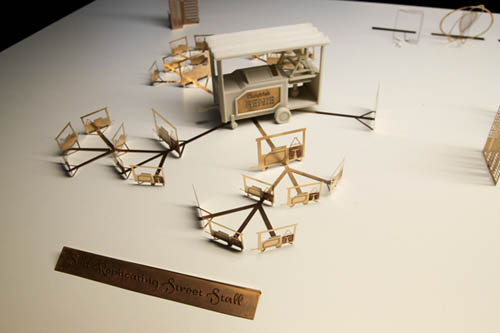

[Image: Mobile Manufacturing Unit by David Benqué].There are Self-Replicating Street Stalls and much more in this circusization of street capitalism, post-Fordist productivity fractalizing into every available spatial niche like economic caulk.

[Image: A Self-Replicating Street Stall by David Benqué].

[Image: A Self-Replicating Street Stall by David Benqué].In the process, it's actually quite an interesting question: what architectural forms would flexible, micro-factory-based, socially temporary production really take? Or do the streetscapes of cities as diverse as Lagos and Hong Kong already provide us with an answer to that question?

A while back, we looked street-vendor rights in New York City, courtesy of designer Candy Chang—but what future rights and tools will we see when, say, mobile steel mills roll through the streets of Queens, counterfeit 3D-printing operations park themselves in basements on Canal, or desalination plants on wheels set up shop for three weeks on the SW corner of Nassau and Fulton? How will the 21st century western city be reshaped when it becomes part circus, part factory, part bazaar?

Comments are moderated.

If it's not spam, it will appear here shortly!

The so-called fabrication revolution strikes me as a chattering-class "discovery" of the creativity and ingenuity displayed by tooled-up hobbyists since the advent of leisure time and disposable income.

Is fabrication really the bottleneck? I'm a software engineer with a well-appointed workshop and a credit card, so I can and do already fabricate fabricate pretty much anything I want in wood, metal or tech in the pack-of-cards- to house-sized spectrum. My stoner high-school classmates were throwing off intricate scratch-fabbed machinery way before that. I'm all for laser cutters and 3D printers, but I submit that the democratization of shade-tree industrial design is many decades old and going strong.

Post a Comment