Air Hive

[Image: From "Microclimates" by PostlerFerguson].

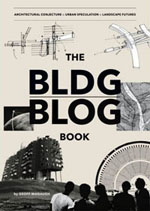

[Image: From "Microclimates" by PostlerFerguson].These air-cooling hives made from "3D-printed sand" and designed by PostlerFerguson have been rendered a bit too glossily for my taste, but I love the idea: each unit has "a complex internal structure whose large internal surface area efficiently conditions air passing through it by evaporative cooling. Each cooling tower is made from 3D-printed sand using technology developed by D-Shape."

[Images: From "Microclimates" by PostlerFerguson].

[Images: From "Microclimates" by PostlerFerguson].The designers refer to the work as "not just an installation, but a building language that can be reused again and again to create new public spaces." Roads, piazzas, buildings, halls, rooms, architectural ornament—adding non-electrical air-cooling technology to the built environment on a huge variety of scales and conjuring up images of 3D-printed sandstone ornamental cornices on buildings being used to cool urban streetscapes.

[Image: From "Microclimates" by PostlerFerguson].

[Image: From "Microclimates" by PostlerFerguson].In some ways, purely on the level of material similarities, this might remind readers of the work of Magnus Larsson, featured here last summer, in which it was proposed that landscape-scale architectural forms in the African desert could be "printed" into existence via bacterial-injection machines (read the original proposal for more information).

[Images: From "Microclimates" by PostlerFerguson].

[Images: From "Microclimates" by PostlerFerguson].But the very different aesthetic here, and the functional purpose of using hives of 3D-printed sand as a way of generating thermally advantageous microclimates in the city, offers an interesting direction for the surprising popularity today of architectural projects involving stabilized sand.

(Spotted via Dezeen).

Comments are moderated.

If it's not spam, it will appear here shortly!

nice! but... how efficient will they be?

WW

It would be really interesting to see how local wildlife and plantlife would interact with these. Would they clog them up by nesting/growing all over these sources of damp, cool air?

Post a Comment